A&A CORVETTE C5 SUPERCHARGER SYSTEM

INSTALLATION INSTRUCTIONS FOR THE C5 CORVETTE

A&A CORVETTE PERFORMANCE C5 SUPERCHARGER

GETTING STARTED

Proper installation of this supercharger kit requires general automotive mechanic knowledge and experience. Please browse through each step of this instruction manual prior to beginning the installation to determine if you should refer the job to a professional installer/technician. Custom PCM calibration based on specific vehicle and engine modifications will be required for use with this kit. A&A Corvette does not include custom tuning with supercharger kits. We can, however, provide you with a “Base” tune. (California cars running our CARB compliant system will receive an approved calibration from A&A.) This will allow the car will start with the large injectors and make the car drivable, so you can drive it to a dyno shop for custom tuning. Please contact A&A Corvette for more information. If you own a 1997-2002 model, you will be installing a new in-tank fuel pump. You will want to have as little fuel as possible in the tank before you start! Also, if you have a 1997-2002, you should change your power steering/alternator bracket to a later style, please see Section 3 of this manual for more information.

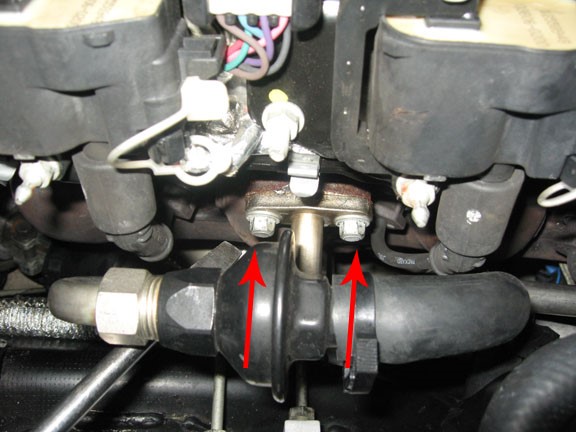

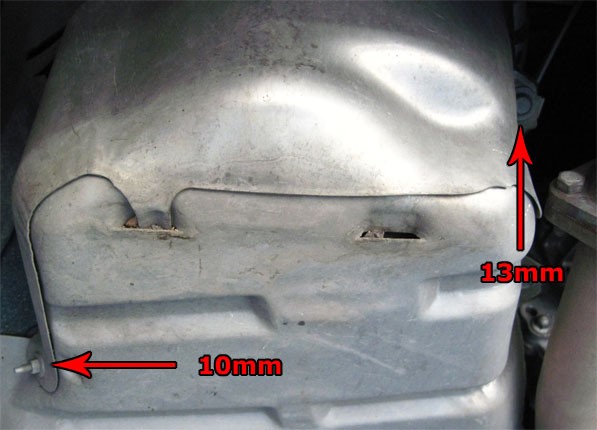

(REMOVE TWO 10mm BOLTS)

(FUEL RAIL BOLTS AND SCHRADER VALVE)

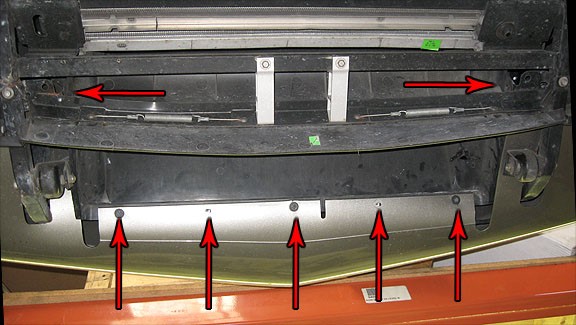

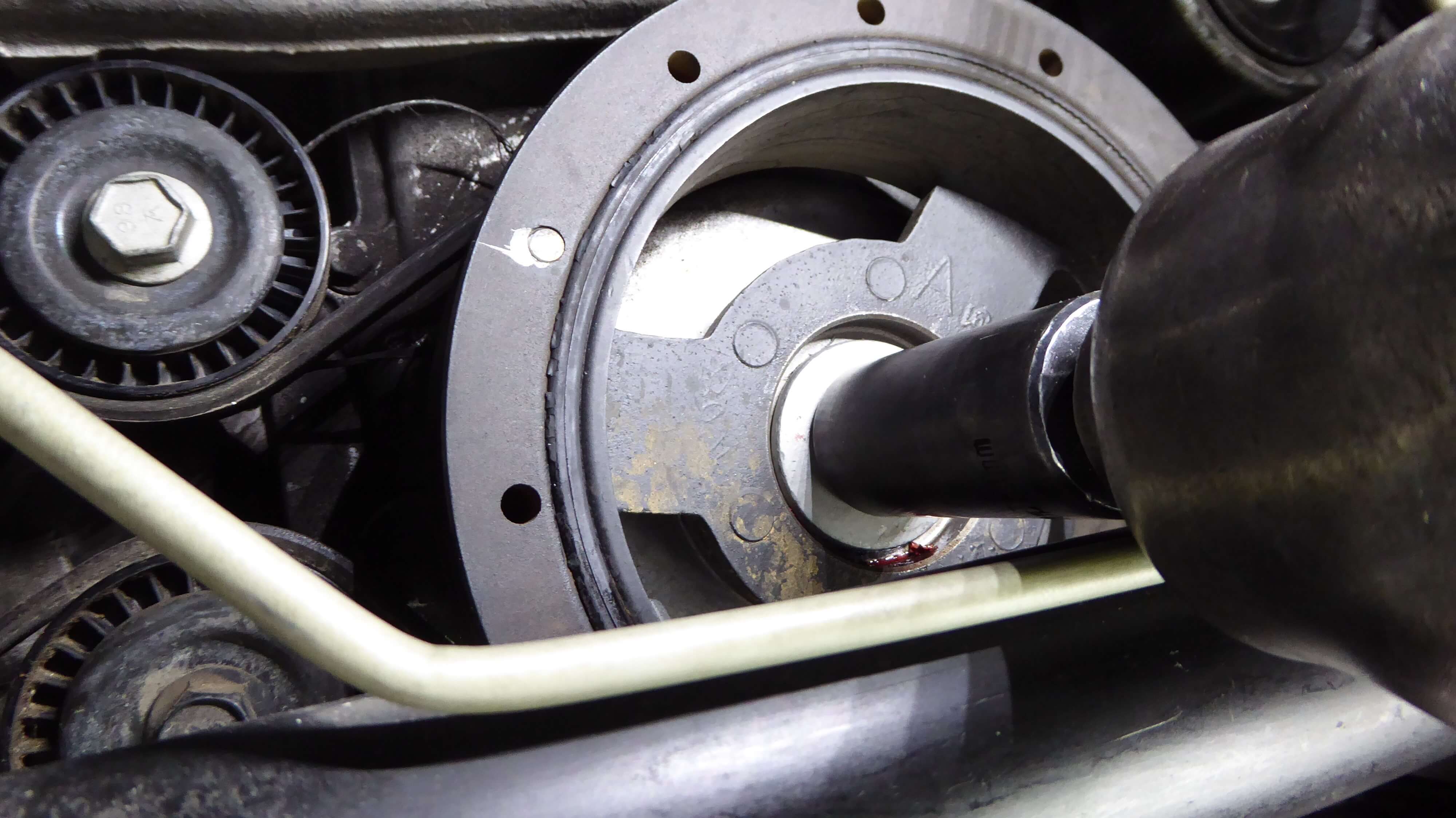

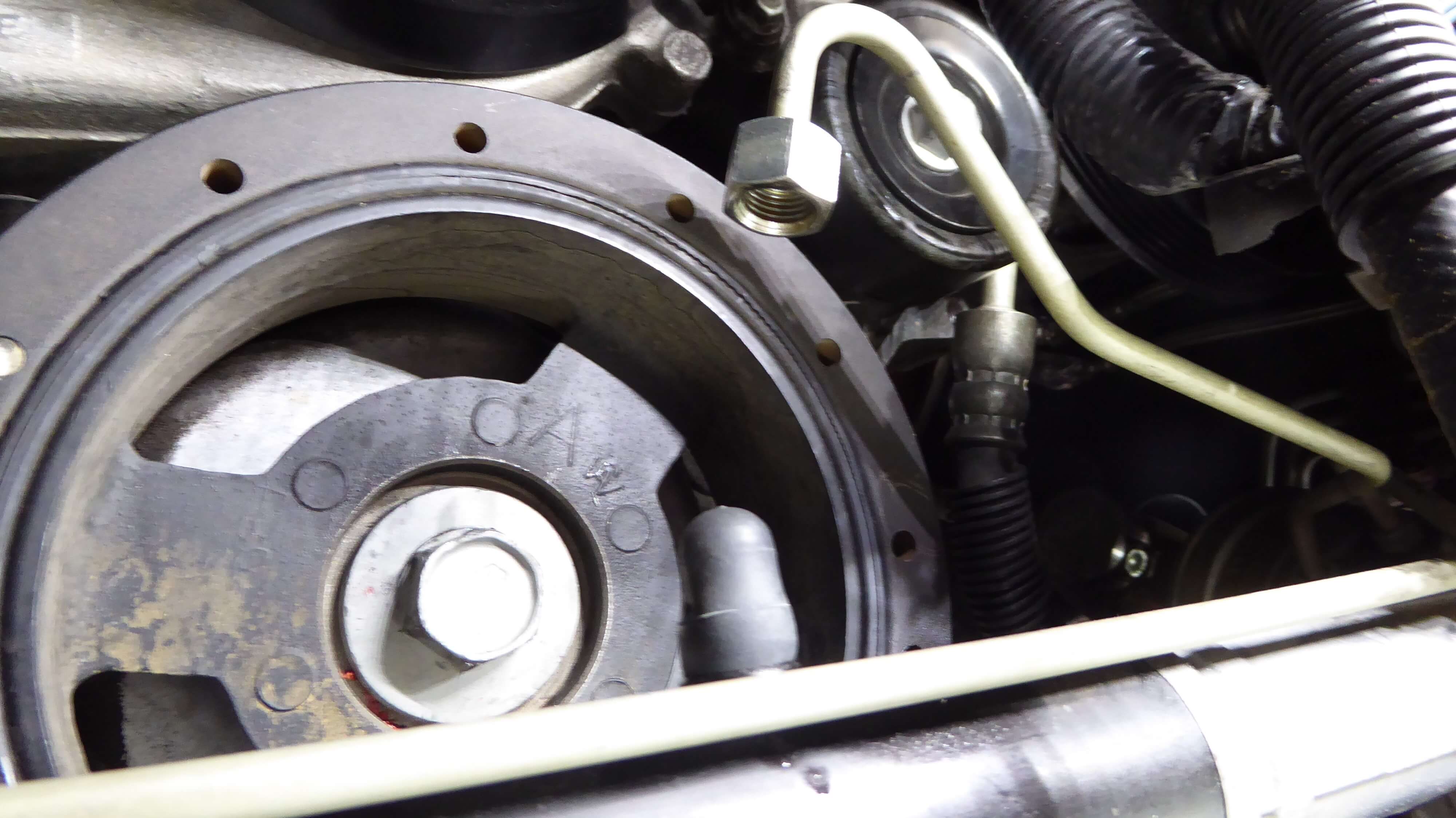

PINNING THE CRANKSHAFT PULLEY: THE STEERING RACK DOES NOT NEED TO BE REMOVED TO PIN THE CRANKSHAFT

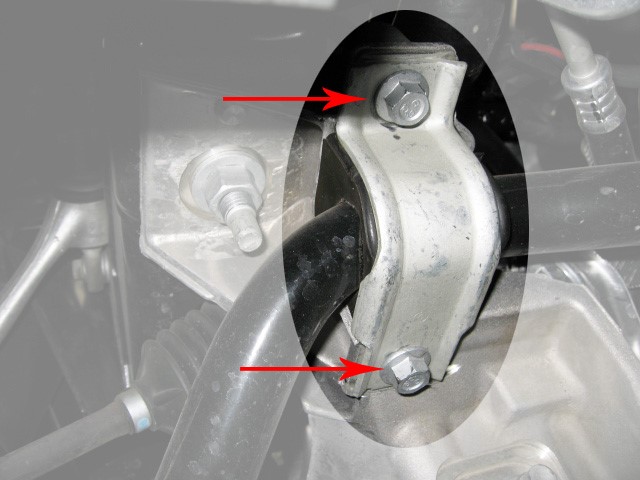

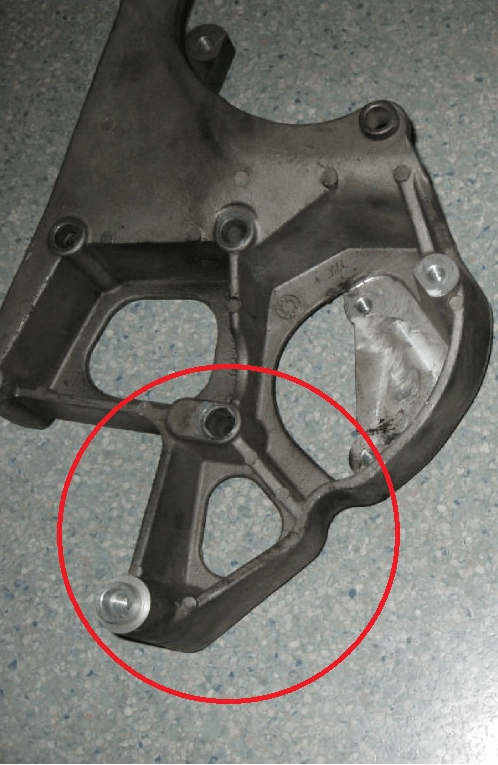

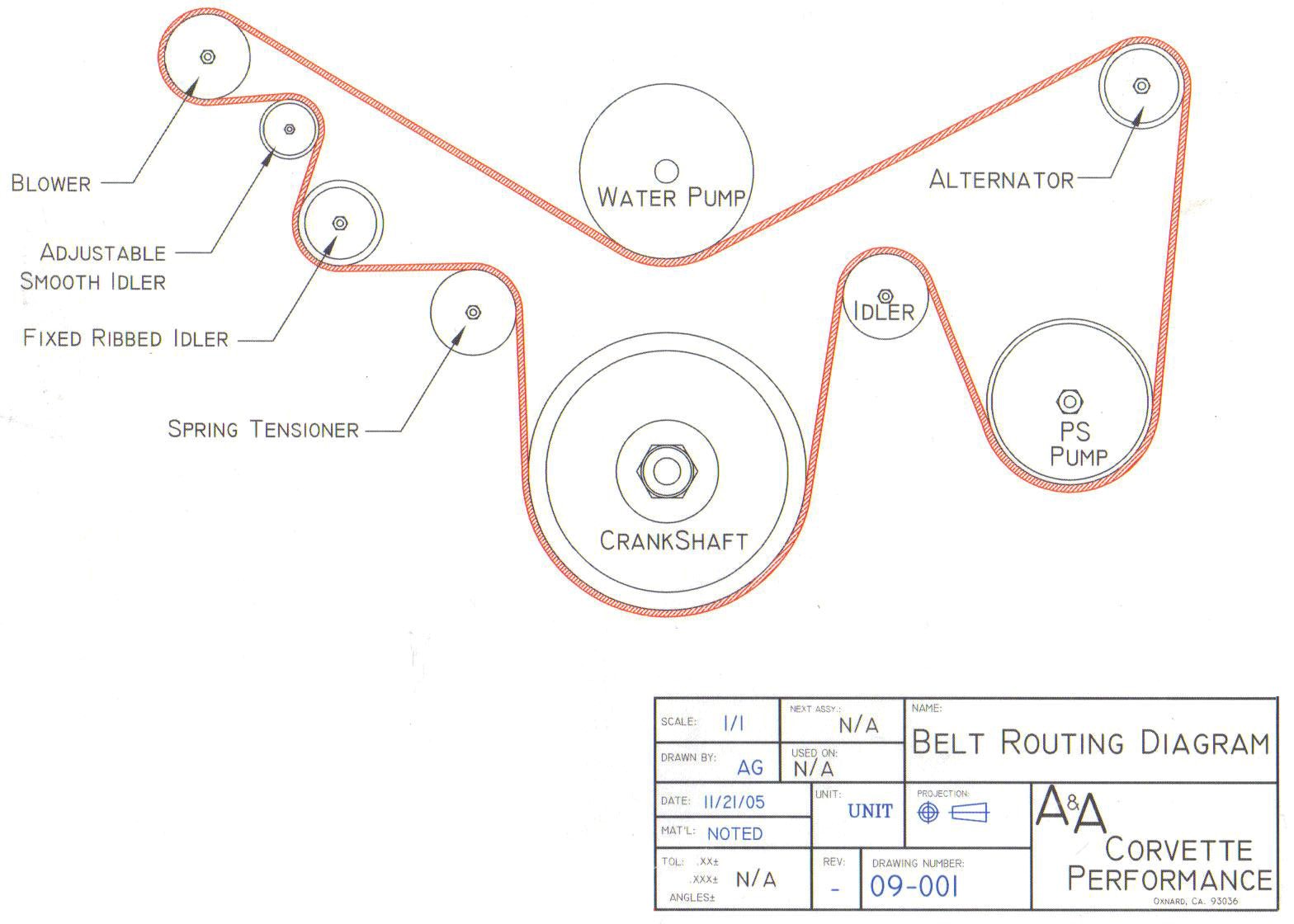

There are two styles of alternator power steering brackets. Chevrolet changed the design in 2003. The early style is very weak and prone to breakage. The new style is much stronger. They are about $120 at your dealer. We recommend you have the later style. (GM# 12578068) The following picture shows the difference.

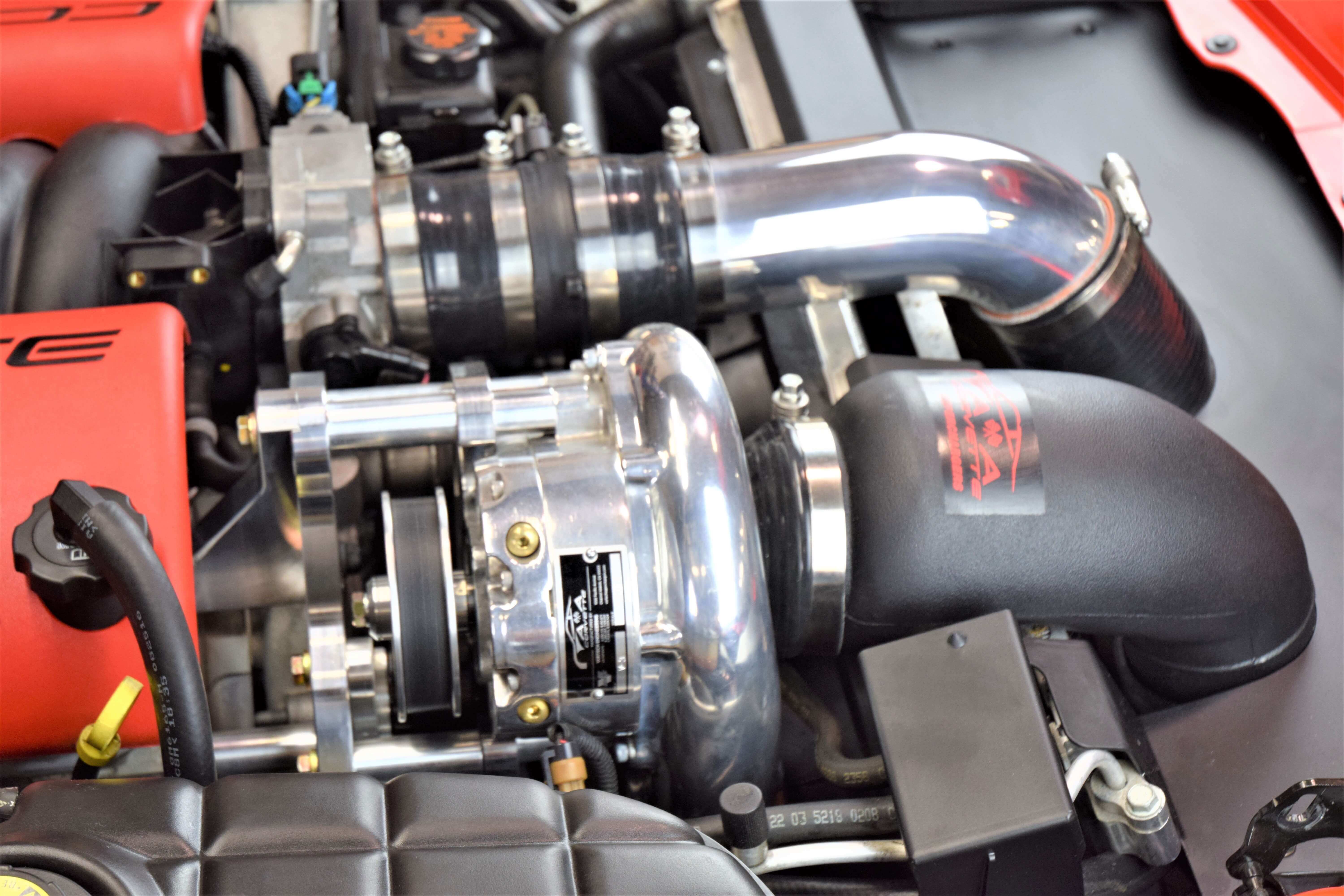

(NOTE: This entire section applies ONLY to the standard “engine oiled” units. For V3 “self- contained” units, please go to step 5.)

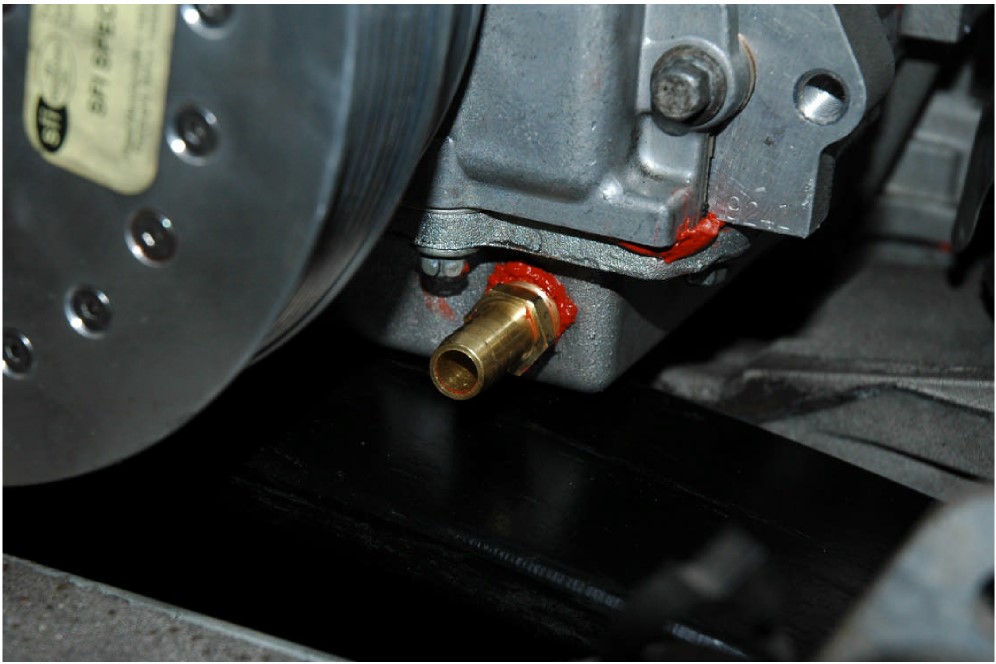

The preferred method of draining the oil from the supercharger to the sump is by cutting and tapping a 3/8” pipe fitting directly into the front of the oil pan.

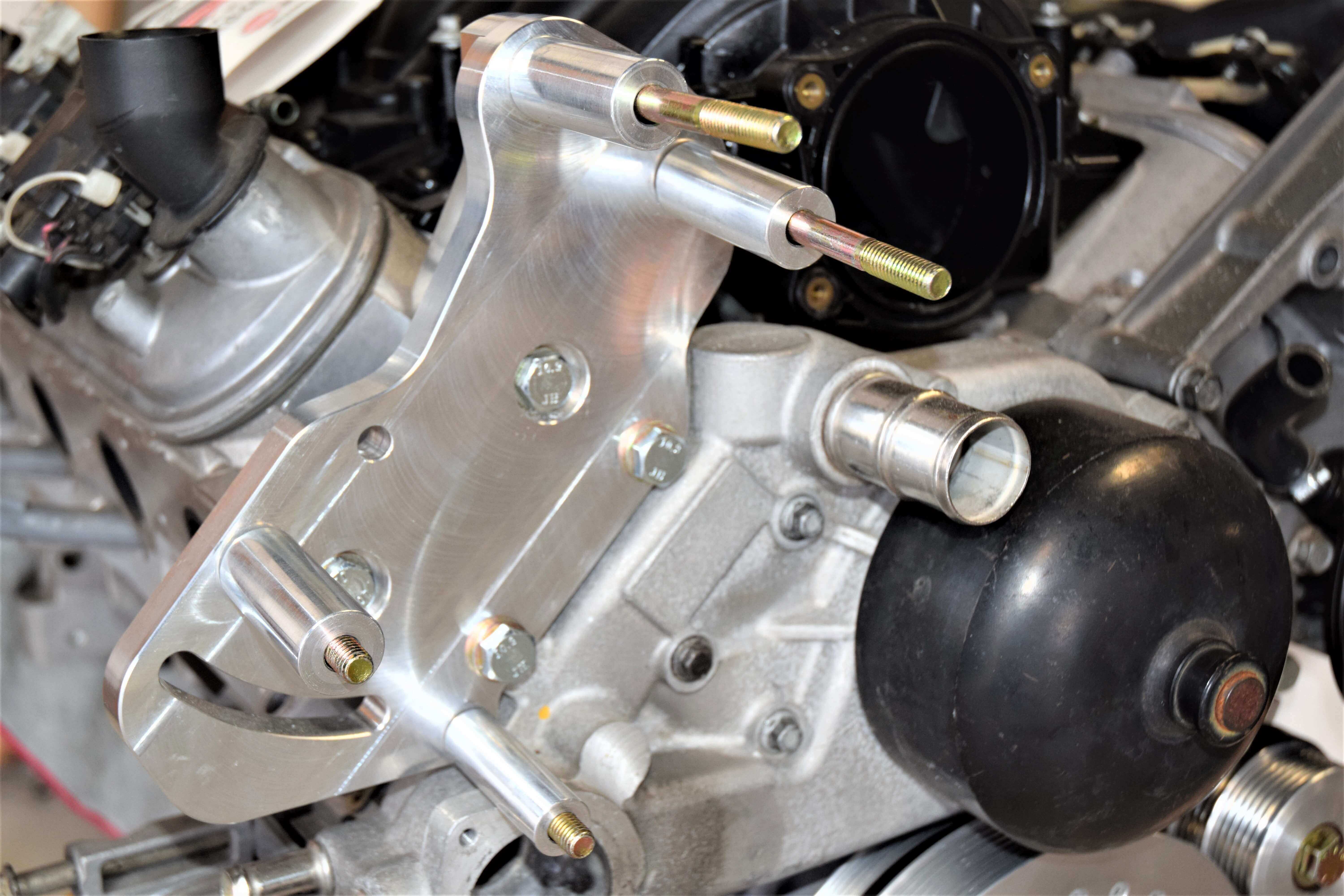

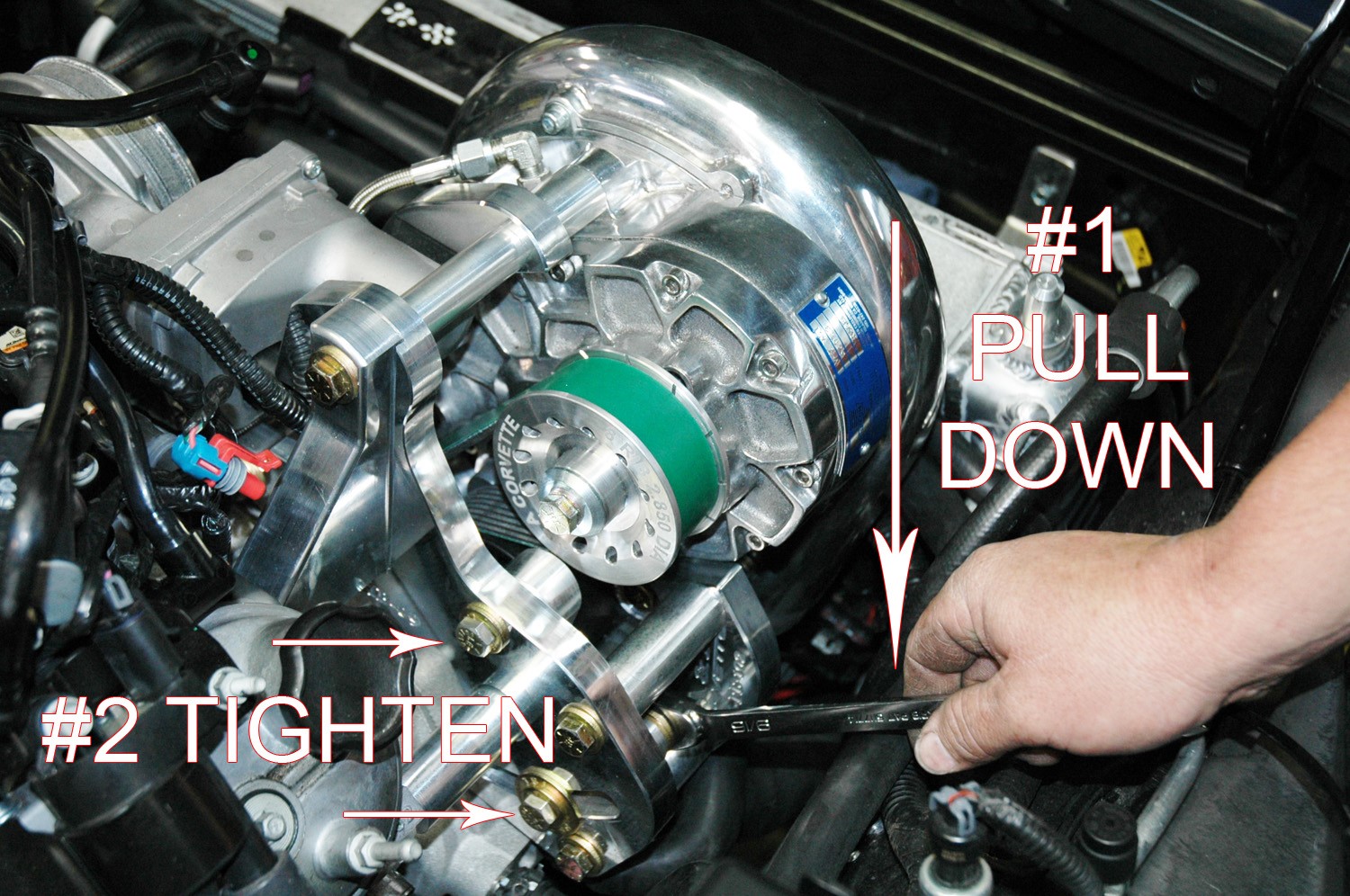

The rear bracket comes with the adjustable idler attached. We do this to make it easier for the installer to understand how the bracket assembly works. Remember how the sliding idler is attached, remove it and set aside. You will reinstall this after the main supercharger bracket is installed.

The rear bracket bolts to the water pump, using the (2) stock tensioner bolts and holes. It also bolts to the cylinder head with the M10x90mm bolts, a 2.460” spacer and the thick angle brace. Make sure you use a THIN washer on the M10 bolt that goes through the bracket and round spacer to the cylinder head. It’s also important to install the lower of the 2 long bolts that attach the supercharger/main bracket assembly through the rear bracket before mounting it to the engine. The intake manifold or cylinder head will not allow them to be installed afterwards. The spacer closest to the water pump is ¾” in diameter.

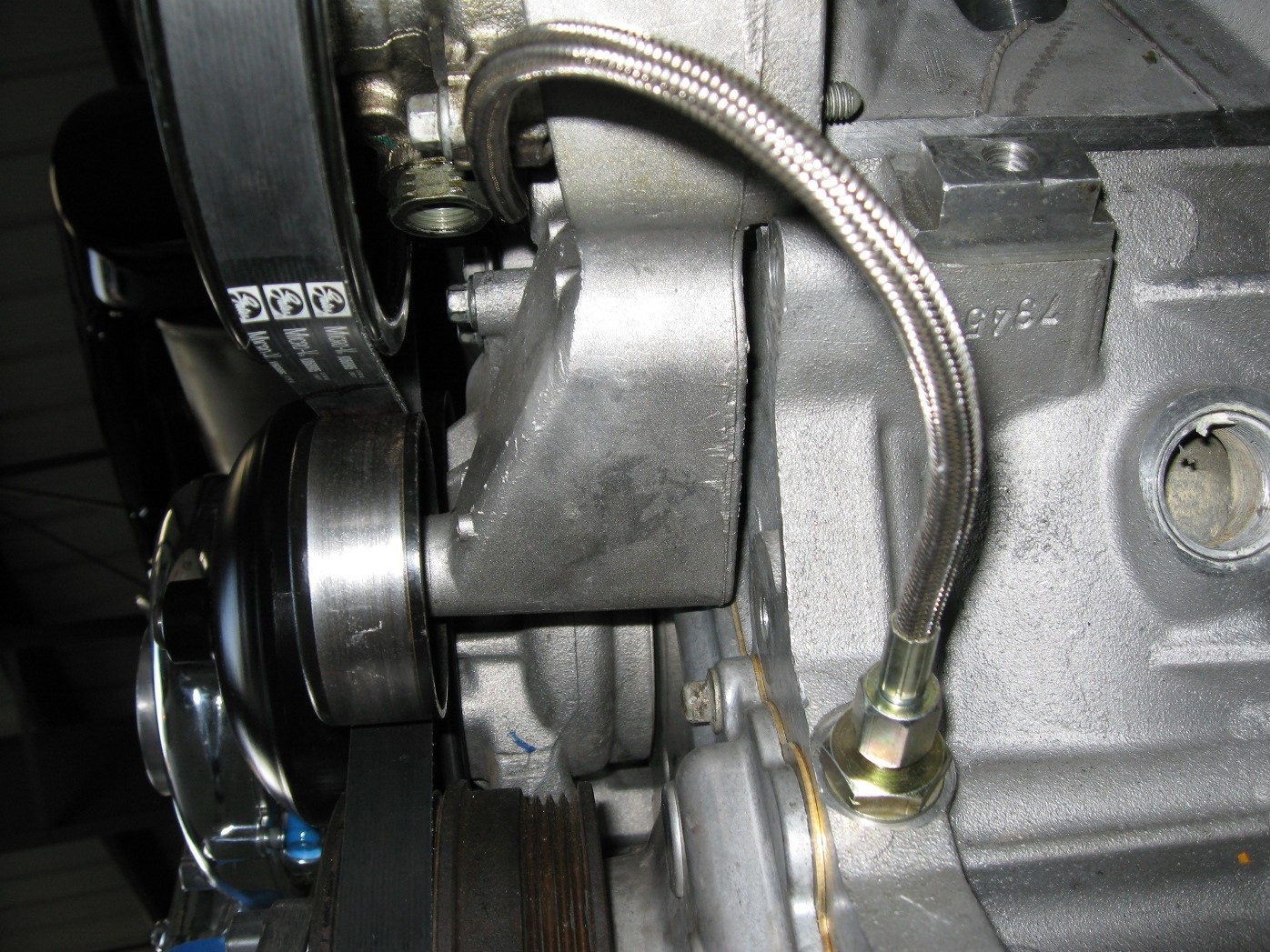

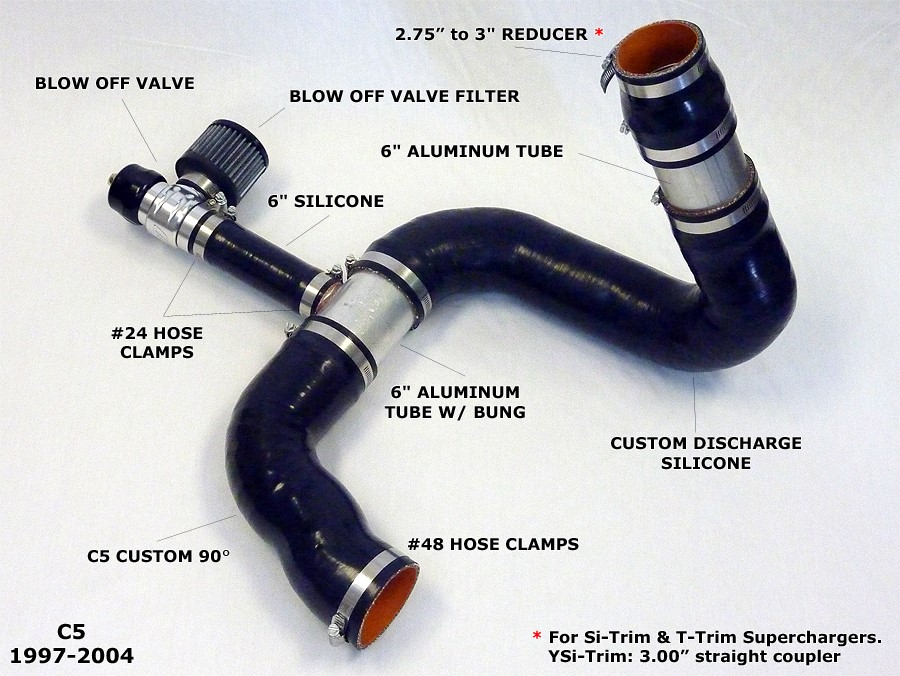

On V1, V2, and V7 models ONLY, you will need to connect the oil drain line to the supercharger before mounting it to the bracket. We use stainless AN line and it is extremely tight in this area. The line MUST be oriented as shown in the picture to avoid contact with the tensioner. Double check this clearance after the installation is complete.

| K060900 | K060905 | K060910 | K060915 | |

|---|---|---|---|---|

| 3.40” | BEST FIT | FITS | ||

| 3.60" | BEST FIT | FITS | ||

| 3.80" | BEST FIT | FITS | ||

| 4.00" | BEST FIT |

| K080903 | K080910 | K080922 | K080939 | |

|---|---|---|---|---|

| 3.125” | FITS | FITS | ||

| 3.33" | FITS | FITS | ||

| 3.47" | FITS | |||

| 3.60" | FITS | |||

| 3.80" | FITS | FITS | ||

| 4.00" | FITS | FITS |

We want you to have the best experience possible when dealing with us both before and after the sale. You can always talk to a sales manager, the owner and head designer, or one of our techs who is infinitely knowledgeable on how the products operate and are installed. You won’t get a minimum wage customer service rep that knows nothing outside his or her script. You’ll get great advice based on many years of experience every time.

We’re happy to help you with your DIY install questions or product inquiries even after hours. The phones forward to either a Manager or Owner to help with both. Remembering that we are on Pacific time, you can generally get help until 9PM on weekdays and weekends alike. It’s something we started when the company was very young and have found it to be an invaluable resource to our customers.

SHARE THIS PAGE!